|

"Nothing like a bit of man-made lightning When two contacts are just too close for comfort, the probability for ionised air to form between them increases dramatically. As the ionised space allows current to start flowing it 'feeds' the ionisation process and the space becomes super-ionised thus allowing serious current to flow. The current creates heat, the heat melts the contacts, and the metal vapour feeds the ionised path with even more conductive particles! The result is an unwanted arc. There are two consequences; Arc Walking (sometimes called 'creepage'), and Arc Tracking. The first occurs with the original arc, the second as evidence of the arc. We deal with each.

Arc Walking is a phenomena experienced by more people than would originally be thought - but because it is on a much larger scale, people tend not to equate it with what can occur with electrical devices and networks. Lightning! Yip, ever seen a lightning strike "walk"? This is where the strike forms between the cloud and ground and starts to 'bend' towards other objects on the ground. It's quite something to experience. This occurs through an ionised 'cloud' forming at ground level where the 'cloud' of ionised air now encompasses other conductive objects that can also partake in conducting the current from the rain cloud to ground. The objects with the lowest resistance tend to be the final point of the 'walk'

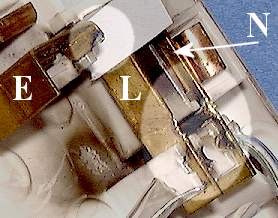

But, notice how the Earth strip (lifted out and masked for clarity) has managed to get involved as the arc flashed across from Live. In this instance the 20A breaker feeding the circuit tripped before the 13A fuse even had time to realize excess current was being drawn. However, if this were a large switchboard, things may have been a whole lot different! On a bigger scale, the same can occur within an electrical switchboard. An arc forms at some point within the board (we'll dispense with the reason for the arc for now), and a small ion cloud forms. This cloud manages to encompass another contact within the board which is at a different potential to the one where the original arc formed, and is therefore able to use the ionised space for current flow. The cloud thus manages to grow and encompass another contact at a different potential (which, in 3-phase panels, is not entirely impossible!), and it can be seen the arc manages to 'walk' through the complete switchboard. This has more chance of occurring on lower voltage switchboards - our friends across the Pond are more at risk with 120/208V as opposed to us with 230/400V as their breakers are twice the trip current to allow the same amount of power consumption. Remember the golden rule - voltage does not kill, it's current that does! The walking arc is dependent on current to 'feed' the ion cloud as opposed to voltage. And with lower voltages making higher currents available... Bingo! A further complication with lower voltages is the arc, not being a perfect short, may only cause a fault current that is below the trip current of the breaker on the circuit with the arc - so the ion cloud is being fed with all the gusto it wants, and can grow to its heart's content. At higher voltages the arcs tend to 'look' more like dead shorts and breakers operate with relative ease. Even if the resistance of the arc was low enough to allow sufficient current to flow to trip the breaker, the current is well below that of a dead short and the disconnect time (the "trip time") is far longer than when tripping under a dead short. This allows massive amounts of energy to be released - the heat alone can destroy a complete switchboard! To this end, "Arc Fault Circuit Interrupters" (AFCIs) are employed (bit of a bad term, but thankfully they're stuck with it, not us!). These detect the current waveform of an arc developing and trip before any real damage is done. Sadly, they appear to also suffer from unwanted trips through the breaker detecting things like arc welders! AFCIs are seldom (if ever) employed on 230/400V switchboards as the arc, although it increases the fault resistance thus decreasing the fault current, still allows sufficient current to flow and is usually well above the breaker trip current and thus satisfies the disconnect times required to contain the fault energy.

If breakdown occurs across (especially) insulators, then a feint trace of cooled vaporised metal that was heated during the flash-over is now left deposited between the two points of the flash-over. As well as the metal trace, the heat also burns anything in site and, what cannot melt and vaporise, turns into carbon and is also deposited on the insulating surface. Effectively, the insulating barrier is now drastically reduced. If the voltage is high enough to jump this reduced barrier, then it will. There is one subtle difference between this and the flash-over; the deposits are a high resistance and therefore limit the current. The result is usually nothing more than irritating scratches heard on local MW radios. Don't forget that the wire attached to this point acts as a superb antenna! Every-so-often the ionised air manages to allow the two points to again be bridged and further flash-overs happen. This simply enhances the deposited material and the frequency of flash-overs rises. If this is external then the slightest bit of moisture only adds to the problem. Believe it or not, this problem is easily traced using two means being a MW radio to locate the approximate area, and then a supersonic microphone (usually mounted in a parabolic dish) to locate the offending insulator. Complaints of "crackly radio" should never be ignored - they could very well reduce the power outages in an area!

© 15.12.02 / 03.02.05 |

CAUSES:

CAUSES: